Weapons Systems Tuning Group Reunion

© WSTG Reunion Committee 2016

Go to top of page

Ivan Winter

Life in WSTG 19/6/61 to 13/3/96

Prior to joining WSTG

In 1960, after completing an electrical fitter apprenticeship, I was employed as an electrical fitter in the Radio Centre in H M Dockyard Chatham.

My duties were assisting in the setting to work of electronic equipment after it had been refurbished in the centre. It must be remembered that in 1960 all warships underwent short and long refits when much of the equipment would be removed and refurbished up to as new in the dockyard workshops.

In Chatham we had three electrical/electronic workshops. The old electrical shop where motors and heavy equipment were refurbished. I can remember submarine propulsion electrical motors among many others undergoing tests. These were about 10 feet in diameter. The new shop where work on lighter equipment was undertaken. For example I worked as an apprentice on preparing multiple deck and bulkhead glands and with another section who repaired search lights where the old silver anodes were much coveted but later thrown away as being too dangerous to be found on you.

The new shop also had a general engineering section where what could not be repaired was remanufactured, this included a tool room and a section where the apprentices would be trained on various machine tools

The latest addition was the radio centre, post war I believe, where all radar, communications and sonar equipment was repaired and then went into test bays and set to work and tested to the original specifications. The Radio Centre also successfully competed for large contracts to refurbish batches of equipment.

After a short time on the repair benches, which I did not enjoy, I progressed to the testing and tuning bays. As a test I was given an old submarine radar to play with and hopefully get working. This was a Type 267 with a yaggi array as an antenna. After some weeks I managed to get echoes from the set with the aerial pointing down the river.

Unfortunately the transmitter transformer blew up, a common problem I was told, and no new one could be found.

I presume I passed the test and continued working with the diagnosticians [Jim Craigie and Mike Jonas] on such equipments as the 89Q radio transmitter, 262 and 293 radars in the radio centre. Afloat on LCT Messina [under water telephone], HMS Diamond including sea trials at Portsmouth and a protracted period on the new Chatham built HMS Oberon setting to work the new radar Type 1000. I was fortunate to be working for a diagnostician [Styles] who let me do all the work including basin trials and then refused to go on sea trials at Rothsey on the Kyle’s of Bute. So I went with Jimmy Craigie -

In the autumn of 1960 an AFO came round asking for volunteers to join the Weapon System Tuning Group based in Portsmouth for mobile duties.

This offered promotion, a job on electronic equipment and a move to Hampshire. [I had been an evacuee for six years on the edge of the New Forest at Landford and wanted to get back to this area].

I duly volunteered and was informed in the New Year that I had been successful and would join WSTG on the 19th June after completing some post HNC exams. Some effort was made to keep me at Chatham by promoting me to acting diagnostician on the 24th May and promising me that I could become their Type 903 expert but aged 24 I wanted to be off. This did mean that I could get a larger transfer grant.

The appointment list rather strangely also included Mr L T S Brenchely who unknown to him had been volunteered by one of his enemies, he was given less than a week’s notice to move and was unable to avoid the transfer. [Different days].

In a fit of pique he refused to move his family until his three-

18th June 1961 until 1st Jan 1967

The Weapon System Tuning Group had been set up on 1 Aug 1959 with Captain G J B Noell as its head. Mr L D Marks with Bill Gerrish as his deputy headed the Bath office; it evolved from the Outside Erection Group run by Mr J Wedge. As I understand, it was recognised that with the introduction of ever more sophisticated warships such as the Leanders and County class DLGs an organisation was required that would have the capability of not only setting to work equipments but also integrating them into effective weapon systems.

The terms of reference of WSTG were as follows:

To set to work: bring equipment from its installation by a shipbuilder; dockyard or shore establishment up to a completely operational state and after harbour and sea trials conducted with the CWTA [Captain Weapons Trials and Acceptance Authority] hand it over to the user authority.

If the equipment was a first fit in the Fleet then the designing project had the responsibility to prove the first outfit after an installation inspection trial by CWTA. At the installation the project had to provide an installation document, books of reference BRs, testing and tuning spares, test equipment and long term spares.

Once the project had proven the first fit all subsequent fits were the responsibility of WSTG, training having been provided during the first fit or by a Collingwood course.

If the WSTG fit was in a Royal Dockyard then WSTG would usually allow over the shoulder training to dockyard staff.

WSTG would thus cover equipment fitted on: -

In the latter case Foreign Governments usually wanted and paid for the same STW as the RN.

WSTG Set To Work all Radar, Sonar, Communications, missile systems, action information systems, electronic warfare, anti submarine weapons [LIMBO Mk 10, IKARA etc] and smaller guns. The exceptions being the 4.5 Gun and Strategic systems such as POLARIS and TRIDENT.

The Outside Erection group appears to have been manned by a high proportion of ex-

The DLGs and Leanders in particular were to have many new equipments. An extensive recruiting campaign started in 1959 to bring in young blood with up to date knowledge.

Many of these new faces were to spend many years in WSTG, giving it an unrivalled expertise at small cost to the MOD.

On 18th June I travelled to Portsmouth on my 350cc matchless and found my digs in Chelsea Road, Southsea. The following morning I reported at No 4 The Parade in the Dockyard to Ernie Brimecombe. He seemed astonished that I had travelled on the Sunday in my own time. First lesson in WSTG, always travel in the firm’s time.

If Ernie was a gent’ the real local head at that time was less so. Charlie Myles was an intolerant type of chap who became very stressed when we were joined by a naval officer by the name of Martin who was Charlie’s boss. Mr Myles later disappeared on sick leave and retirement.

This was my first time away from home and being an introvert with little to say for myself, I was finding life a little difficult. For example Charlie breezed into the office and announced that I would be going to Belfast next Monday so get it all sorted. I was even unused and alarmed about using a telephone. Mr Len Brenchely, who was also going, was his usual unhelpful self but it eventually got sorted and Len, Phillip Pollard and myself set off for Shorts in Belfast to attend a Seacat acquaint.

As a first trip away this was not bad with long train journeys, a ferry to Belfast, and then a visit to the Shorts aircraft factory which used to be in Rochester, where I went to school.

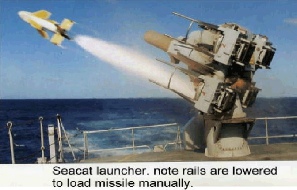

The Seacat was quite interesting particularly the cordite fired run up of the gyro. We only saw the missile and launcher as the electronics were made by PYE. However, the Belfast transport aircraft in build was awesome!

On the return to Portsmouth we had to wait for the first of the Battle class destroyers, then in refit. Our first WSTG ship at Chatham Dockyard was HMS Aisne.

Equipment on the four Battle Class Destroyers

This involved the fitting of a double bedstead Aerial 965, an MRS8 Radar 262 director with a quadruple Seacat launcher GWS 21.

This involved the fitting of a double bedstead Aerial 965, an MRS8 Radar 262 director with a quadruple Seacat launcher GWS 21.

The Seacat was the first missile to be fitted in the RN. It was a ship to air anti-

L ate in 1961 we started work on HMS Aisne with staff from Devonport looking over our shoulders so that they could Set to Work their ship HMS Barrosa.

ate in 1961 we started work on HMS Aisne with staff from Devonport looking over our shoulders so that they could Set to Work their ship HMS Barrosa.

I was involved in the Seacat electronics, the MAA, built by PYE. Thermionic Valves of course. There were a few design problems including incorrect wiring of the aimer’s joystick. That would have made the sea trial interesting.

The sequence of events, which remained the same throughout the life of WSTG was, Installation inspection, setting to work, harbour trial and sea trial.

In this case it included firing of the missile, making HMS Aisne the second RN ship to have an operational system. Note double bedstead aerial fitted with the Radar 965, MRS8 director [covered aft of the 277Q height finding aerial] and the four round seacat launcher, also covered.

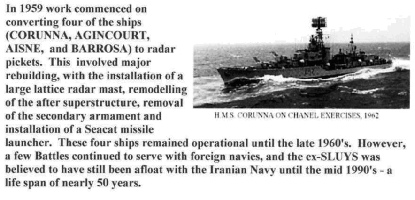

The next ship was HMS Corunna at Rosyth Naval Base with John Farmer as our boss. I spent many weeks on this job staying at the Royal hotel in Inverkeithing.

Only one panic occurred when the secret crystals were left out. A quick dash back to the naval base solved that problem before heads would have rolled!

Other ships converted were Agincourt and Barrosa at Portsmouth and Devonport. Agincourt being first of class was set to work by the project-

MoD(N) then went into a period of intense building through the 1960s with the Tribals, Leanders and the county class DLGs coming from the many shipyards dotted around the UK, i.e, those on the Clyde and Tyne, at Belfast, Southampton, Cowes, Birkenhead, Barrow, Portsmouth and Devonport dockyards.

I was involved in many types of equipment at this time as Charlie Miles policy was to get everybody out of the Portsmouth office. This resulted in packs of staff descending on ships. I worked on HMS Devonshire’s GDS5, with John Farmer as boss and with about five others. This was not an easy system, as it required continuous readjustment of the many servo systems. Devonshire was built at Cammell Lairds at Birkenhead to which I travelled on my 350 Matchless motorbike. I soon realised that travelling longer distances really needed a car. In 1963 I bought my first Volkswagen Beetle and travelled 30000 miles in the first year I had it and then spectacularly rolled it on an “S” bend near Sevenoaks, landing it on it’s roof leaving me to crawl out unharmed.

As a member of the radar group I worked on general equipment such as the Seacat electronics, displays, video and sync distribution units and the navigation radar 974, which was made by Decca. Early displays had a problem with linearity; this had been solved with more complex designs producing the required sawtooth, different ranges and various types of received image; i.e. linear, logarithmic etc. The rotation was supplied from a separate unit; the PAB slaved to the appropriate radar aerial and producing SIN and COS outputs.

In the early 1960s all equipment was driven by valves, a concession to modernity being the smaller types. Double diodes, triodes, pentodes or even double diode triodes and pentodes were the norm. An essential piece of equipment was the valve tester, which involved setting the valve type, CV number, and setting all of the appropriate voltages for heaters anode, grid and cathode. The first check was a visual inspection to see if any valves glowed blue, which was an indication of loss of vacuum.

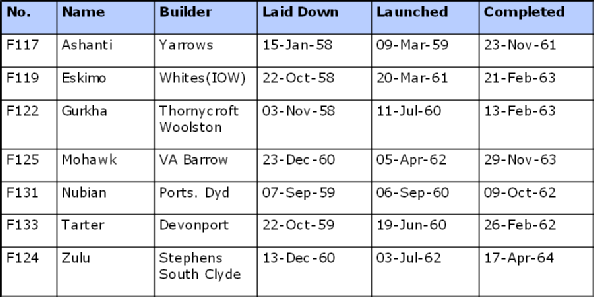

Coming back to ships. In total there were seven Tribals. Ashanti built at Yarrows in Glasgow, Eskimo at Sammy Whites at Cowes, Ghurka at Thornycrofts at Southhampton, Mohawk at Vickers Armstrong at Barrow in Furness, Nubian in Portsmouth Dockyard, Tarter in Devonport Dockyard and Zulu in Stephens’ yard on the south bank of the Clyde.

I only worked on Ashanti at Yarrows, Eskimo at Samuel Whites of Cowes, Ghurkha at Thornycrofts Southampton, and Zulu Stephens south Clyde.

Stephens’ yard on the Clyde was next to the quay where the sewerage barge was berthed. This ship would be filled with raw sewage and then it was dumped at sea. I have known those with sensitive stomachs throw up as we went into the Stephens yard to work.

Glasgow still had its trams at this time, and its many drunks. As payday was on Friday midday those wives who were unable to relieve their men of their wages as they left the yard would have a lean week and of course we would not see their men on the Friday afternoon.

A Typical Tribal weapons fit was two 4.5 /45 MK 5’s [a hand loaded gun for shore bombardment] the LIMBO MK 10 and a Wasp helicopter.

It’s sensors included: Radar 965 [AKE 1 aerial], 993, 974 and later 978, sonar 170, 177, 162.WSTG would of course set to work all of these sensors plus the communication kit and the LIMBO.

The radar team at that time included Ivan Winter, Len Brenchely, Jim Stephens, Norman Dibley. Eric Shoesmith, Trevor Mitchell.

In depth - the Type 81 (Tribal Class) Frigate.

By the mid 1950s, the wisdom of building specialist frigate types was being questioned, particularly on cost grounds and the problems associated with getting the right ships in the right place, at the right time. Design work was initiated on a ship that could integrate most of the specialist functions of the Types 12, 41 and 61 frigates.

The outcome of this design study was the Type 81 tribal class frigate and the first of the new class was ordered in February 1956, despite the design not being finalised until Feb. 1957. The first keel was laid down in January 1958 at Yarrows shipbuilders on the Clyde at Scotstoun. This being F117 HMS Ashanti.

Ships of the class were:-

As previously stated I was involved in STW on Eskimo, Gurkha And Zulu.

The new ships incorporated guided missiles as part of the main armament for the first time. Space was provided for a quadruple Seacat launcher and its associated GWS 21 control system. The target was either tracked visually or by the Type 262 radar in CRBFD [close range blind fire directors] abreast of the after funnel. Due to delays with Seacat, 40mm guns were fitted on all but Zulu initially. Because space was made for a helicopter only a single LIMBO mortar could be fitted.

The main armament consisted of two 4.5 Mk 5 gun mountings. These had come from scrapped “C” class destroyers. Fire control of these was by the MRS3 director and radar 903.

The radar fit set to work by WSTG consisted of the Type 965 long range radar with AKE1 bedstead aerial, a Type 993 medium range with a cheese aerial and Type 978 navigation radar

The Sonar suite stw by WSTG was fairly comprehensive with Types177 scanning sonar, 170 attack sonar, 162 sea floor tracing sonar, 182 decoy sonar e/s and bathythermograph sonars.

I have no details of the communication or electronic warfare fit, which would also have been Set To Work by WSTG staff.

The story continued:-

1962 brought trips to Belfast where HMS Kent and HMS Leander were in build at the same time at Harland and Wolff shipbuilders.

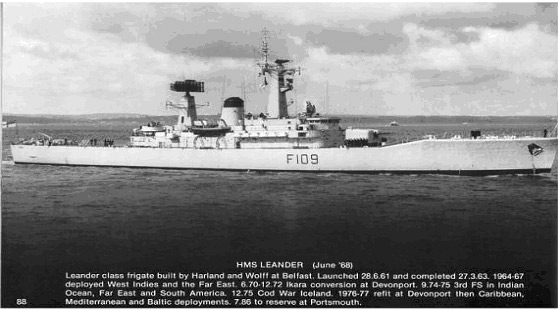

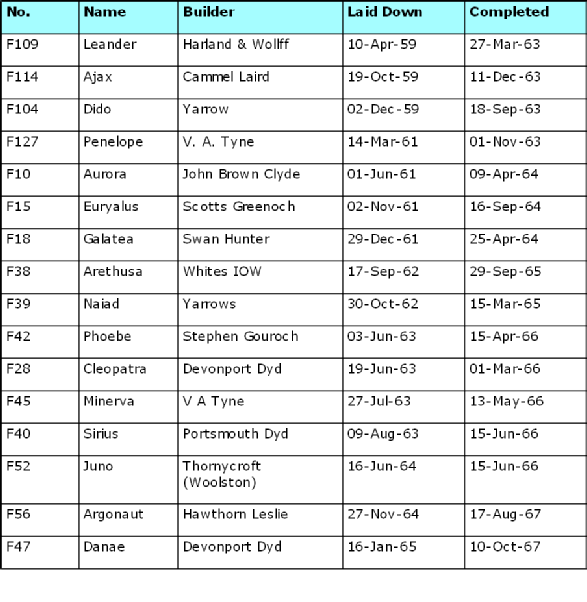

Leander was the first of class of 16 ships built between 1959 and 1965. A very successful class considered by some to be the best escorts ever built for the Royal Navy.

HMS Leander started out in life as HMS Weymouth, the effective hull form having evolved through the Whitby and Rothesay classes. Weymouth, Fowey [Ajax] and Hastings [Dido] all being cancelled and replaced by the Leander design which carried 2-

Sensors included Radar 965[AKE-

(The 965 radar is the large “ bedstead” on the aft mast, the 993 is a ¼ cheese aerial on the mainmast and the 974-

The Leander class in depth

The frigate building programme of the early 1950s had resulted in some 35 vessels of various classes{ Whitby, Salisbury, Leopard and Rothesay}, which gave a good sized fleet of modern escort warships, but resulted in standardisation problems.

The new class was to be known as the Type 12M and its armament was to be a balanced one with twin 4.5 inch guns combined with the new 903 radar, quadruple seacat launchers, 20 mm guns and chaff launchers, Limbo antisubmarine mortar and wasp helicopter.

A variety of Sonars were fitted on the class Types 177 or 184, 170B, 162 and 199 variable depth sonar and the normal fit of minor sonars such as echo sounder.

The radar fit was equally comprehensive with the Type 965, 993 and 974 or 978 navigation radar. The operations room was impressively fitted out with the versatile console system holding much of the units required to pass information from sensors to displays such as the JUA plotting tables, JW [the Philips designed projection display] the dedicated navigation displays and the numerous general displays.

Many of the smaller units were fitted in a space under the Bridge [the bridge annex] not easy to access.

Below the operations room was the radar maintenance office and radar office containing the 978 and 993 and some processing video units.

The 965 and IFF Mk 10 were in another office amidships.

Again I don’t know the comms fit, however, there was fitted an electronic warfare fit consisting of the UA3, FH4 and HF/DF.

The GDS 5 was part of the gun direction system, a collection of difficult to set up servos that always seemed to have a mind of their own.

Ships of class:-

I was not involved in the Broad beam Leanders ten of which were built 1967-

These were the first 16 Leanders which WSTG were heavily involved in setting to work during the 1960s. It is interesting to note the number of competent shipbuilders we had in the UK then.

WSTG was to see many of these warships again during their midlife refits when Ikara, Exocet or Seawolf were fitted in the Four Royal Dockyards. WSTG setting to work the first fit in each case. One Ikara fit was in Gibraltar that made a nice change.

I was involved as the WSTG co-

Leander, Dido, Ajax, Galatea, Aurora [Chatham], Euryalus, Naiad and Arethusa received the Australian designed Ikara anti submarine missile, which carried a torpedo to the target.

Sid Porter [team leader] and Frank Moore were heavily involved with stw and trials which involved many months away at the Andross range and for Sid a long time in Australia.

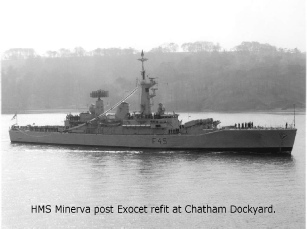

Penelope, Cleopatra, Phoebe, Minerva[chatham], Sirius, Argonaut and Danae received the French Exocet anti ship missile system.

Again members of the group were trained to deal with this new missile, some went to France after high pressure French language courses. Neville Ward, Dave Stoodly, Bob Blofield and Andy Andrews were in that group.

Finally Andromeda, Jupiter, Charybdis and Hermione [Chatham] refitted and received the seawolf system.

I was still in the co-

Hermione had the doubtful distinction of being the last ship to come out of the yard before Thatcher’s dogma of selling off the family silver hit them.

It gives me little satisfaction that where I started my apprenticeship the houses built on St Mary’s Island on the site are on low level nuclear waste.

Other members of WSTG were involved in these refits as weapons across the board were updated.

Sonar 184, a more effective set replaced 177/170, STWS [surface torpedo weapon system] was fitted on the IKARA and Exocet refits radars 994 and 1006 replaced 993 and 978.

The radar 965 was retained on the Exocet refits.

The seawolf conversions required better radar so 993 was replaced by 967/968 .

Better electronic warfare packages saw the 667 or 668 jammer fitted and UA3/4 updated to UA8/9 or 13.

It must be remembered that all of these new fits would have been set to work by WSTG with the dockyard staff looking over their shoulder.

My story continued.

I worked on a few of these Leander class warships between 1962 and 1965. Being in the radar section this was on general equipments including seacat, displays, and distribution equipments for video, sync and aerial rotation. I was also involved in setting to work the navigation radar 974.

The combined radar office was below the operations room and Messrs Brenchely and Hawkins saw it as their domain, even though they only STW the 993 radar. It was an unnecessary and unfortunate approach to working with their colleagues, which made it an intimidating experience to get into this office, the usual greeting being intemperate Anglo Saxon language. This was Brenchely’s approach to life in general which may have been due to an illness that later killed him, liver failure. Barry H just ran with the hound and was a much nicer man on his own.

The mobile nature of our work meant that we could combine the job with a social life, particularly in the long Scottish summers, when the excellent pitch and putt courses were well used. Others of course made use of the local pubs and dance halls, where the southern men would be a pleasant novelty to the Scottish lassies.

Eric Shoesmith, with whom I worked many times made every effort to lead me astray, but his life style was low on my list of priorities. This is a Winter trait that usually led to us Winters marrying late to young wives.

Other Leanders worked on by me were HMS DIDO, HMS AURORA and HMS ARETHUSA.

In this period 1962-

F 145 President Kruger, F147 President Pretorious and F150 President Steyn. The first two at Yarrows on the Clyde and the last at Stephens on the south bank of the Clyde.

These were Rothesay class frigates with a similar weapons fit to the RN Leanders.

On the Isle of Wight Sammy Wight’s shipyard at Cowes was brave enough to take on the refit of two Ex British Z class Destroyers, the EL-

Eric Shoesmith and myself had the task of reviving the 275 Gun control radar fitted in the director above the bridge and its control table fitted in the GDR.

First the ship had to be made safe, as its Ammunition was decidedly dodgy. This was done in Sandown bay before the ship came alongside.

The crew were very friendly but had strict lines of demarcation between officers, who were university educated but would not get their hands dirty, chiefs who seemed to have little idea and the “erks” whose most skilled task would be sheep slaughtering in the bathrooms.

Needless to say nothing worked and I gained instant fame by finding a short circuit to earth which when removed brought up all the lights on the previously dead control table.

Eric and I found that all safety interlocks had been shorted out in an effort to keep the set going

It was an interesting and pleasant experience in the summer on the island made more lively by Eric finding the digs in Cowes. He tended to go for the cheap and cheerful with cheap council house digs high on his list and on another later trip we stayed in the Salvation Army hostel at Portland, which had to be seen to be believed. Still that was Eric and a nicer man would be difficult to find and he did spend many lunch breaks teaching me to play darts in a pub near the chain ferry in Cowes.

On the way into the shipyard the cocooned fuselage of the Saunders Roe Princess lay in a boatyard. It looked quite small and sad as a reminder of Britain’s high hopes after the war. Little did we know that most of our aircraft and shipbuilding industry were to go the same way.

After several trips to Cowes [very nice in the summer] we got standards achieved at the Harbour and sea trials. I don’t think the trials authority were too critical.

Although I did not work on them WSTG also did work on New Zealand warships, the F111 OTAGI, 1960 Thornycrofts and the F148 TARANAKI at J S Whites on the Isle of Wight. both Rothesay class and later two Leanders F55 WAIKATO built at Harland and Wolffs Set to work 1965/1966 and F148 Canterbury built at Yarrows at Scotstoun on the Clyde [I worked on this last one as the radar team leader while I was based at Newcastle].

For some reason Eric Shoesmith and I were seconded to the Seaslug team working on a DLG on the river Tyne and on HMS KENT.

We did some of the boring work of checking relay sequences, which seemed endless. Even this work was enlivened by us inadvertently causing the BAU [beam aiming unit] to move. This plate fitted in the massive aerial steered the radar beam along which the missile travelled. Although we had taken all necessary precautions a foolish Vickers engineer was in the aerial and had the fright of his life. His foul and intemperate language was more than robustly answered by Eric and we were in the right.

As a result of this work I ended up going on the Sea Trials of HMS Kent in the Losiemouth area as John Burroughs the Team Leader decided that everyone who had worked on the equipment should have the perks of going on the sea trials. This involved a flight in a Vickers Vanguard, my first flight ever, from London to Edinburgh. Unfortunately the weather was very rough, which was probably why they wanted to test the equipment off the north of Scotland.

As a result of the adverse conditions I chucked up in the main passageway of the ship, known as “The old Kent road”. Tradition has it that he who chucks up cleans up, but I was so bad that it was done for me.

It was not a good trip as there was little to do, although meant well it would have been better not to go.

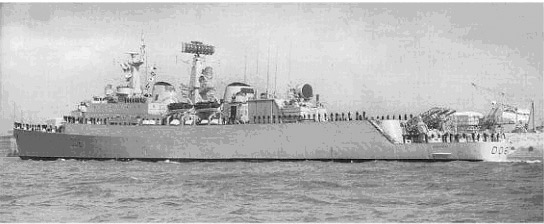

One of the first four DLGs showing to good effect the Seaslug launcher mounted aft and the director. The launcher was a massive structure weighing as much as a gun mounting designed to hold two missiles with four wrap around boosters. This design was selected because the RAE scientists believed, mistakenly that a tandem booster was not stabile. Earlier German missiles and later American were tandem boosted which made for a tidier launching arrangement.

The huge stabilised aerial provided the beam and information to the missile.

The DLGs in depth.

These ships were designed around the huge Seaslug ship to air missile system. The missile was unnecessarily large because British scientists insisted that tandem boosters would be unstable longitudinally, in spite of German wartime design and current American thinking. The resulting missile with four wrapped boosters was massive and needed a large heavy launcher with a tunnel design through the ship to feed it. This design proved difficult to engineer in the shipyards and made the class specific to that missile so when it became obsolete so did the ship.

I continued to work on the first narrow beam Leanders as they were built around the country. HMS Aurora, Euryalus,galatea and Naiad. Still working on general equipment associated with the Radar section.

In 1965 I was selected to be seconded to a project that was developing the 992Q Radar an S band set operating in the 3Ghz range.

In the spring of 1965 I joined the team of project officers, all scientific grades, who were designing, testing and preparing the Radar 992Q for introduction into the fleet.

The project team consisted of Reg Davis, Malcolm Kemp, Ron Saunders and their boss Freddy Frow and a scientific assistant whose name I forget although he and I did much of the setting to work on the first fit.

Freddy Frow seemed to have a massive reputation as one of the wartime early Radar designers. Maybe it was the Radar type 262 that he was involved with.

Putting a WSTG man with a project was not a new idea. It enabled WSTG to get experience for their first fit and it gave the project an extra hand that was used to travelling. Some of the project team were less than enthusiastic about spending nights away.

Reg Davis as ex army [RE?] and Malcolm Kemp did a lot of travelling with me.

The 992 was not a new radar, it’s design went back to 1948 the 992Q was developed from the 992P which had been fitted to the first four of the county class DLGs Devonshire, Hampshire, London, Kent and the cruisers Tiger and Blake. I had no involvement in these 992s they were set to work by Geoff Wells, who I believe was not based in Portsmouth. The aerial on the cruisers had a higher rotation speed; I cannot be sure whether the first four DLGs were the same. If my memory serves me right it also had a different means of generating the high voltage pulse which used several massive valves, which generated a large amount of heat and light. This was rather intimidating when you ran up the transmitter for the first time.

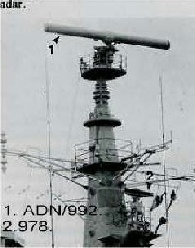

The 992Q had the following improvements. A new linear slotted array aerial in a round fibreglass radome mounted on the existing fully stabilised aerial platform. The whole being called the ADN aerial. The stabilised platform was driven by an Amplidyne fitted in the radar room annex. This device gave very few problems I am glad to say as it was all a bit of a mystery and involved many hours poring over the BRs {books of reference} if a problem arose. The aerial/amplidyne was controlled by a newly designed set of plug in modules in one cabinet, a set for each motion of pitch, roll and azimuth. One aspect of the new aerial was that different frequencies produced a different squint of the beam, which had to be corrected in order to give the correct bearing on a target. Two rotation speeds could be selected 30 or 15 RPM.

The complexity of the stabilisation gave us much work up the top of the mast, not appreciated on a cold day or worse if a failure occurred during sea trials. Magslip and synchro conventions had to be committed to memory or a little black book.

High power air was used to keep the waveguide dry and to release the brakes on the aerial. Crossing over of these airlines by the shipbuilder could wreck seals and drive grease out of rotating waveguide joints as they were at different pressures of 15 and 30 pounds per square inch.

Another error on build was to leave plastic bungs in the waveguide during assembly. The whole shipyard could hear the power breakdown but the foreman would still have to be really convinced before he would sanction the massive task of breaking down the waveguide.

There was great efforts made to improve the signal to noise ratio on the receiver side of the re-

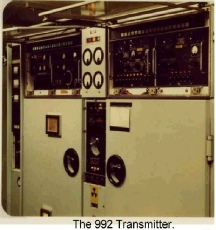

The Transmitter had been reworked considerably. It consisted of one large [3metresX2metres] cabinet. On the right were the units, which controlled the run up of the transmitter, produced the various voltages and controlled and set all of the safety interlocks. The condition of all interlocks was shown at the top of the cabinet, green for set and orange for a failed interlock. The orange lights once set stayed on to let the maintainer know which interlock had tripped and knocked the set off.

The transmitted 2microsecond pulse was generated at S band frequency by a water-

A major innovation in the control design was the use of modules with transistors, although at this stage all components were stand alone and replaceable.

The centre section had all of the meters showing the run up of the transmitter, which was run up by hand. One aspect of this was that the meters ran up and then dipped back as eht was applied and then moved up again, this could and did on one occasion produce a problem for the engineer who had not learnt this lesson.

On joining the project my task was to learn all about this new monster and be capable of setting it to work and take it through harbour and sea trials.

I started by copying drawings as a memory aid and reading the BRs [books of reference] but the best way to learn is always hands on and I was helped by the fact that the project had a set installed in the stores and test facility at ASWE Portsdown where they all worked.

The Projects first fit was on HMS FIFE being built at Fairfields shipyard on the Clyde. In 1965 the scientific assistant and I went up to the Clyde to start the first job.

There where quite a few teething problems and incorrect ships wiring which seems strange considering the amount of work done before the equipment reached the ship.

However there was a good procedure for getting all of these problems into the system on defect reporting forms unfortunately the system was so slow that a fault fed into it on one ship would still be on the last of class. A direct report to the project was also done.

One of my tasks was to produce the critical path diagram. This assembled all of the setting to work activities either in parallel or as series activities. The whole having to show the minimum time required to carry out the setting to work and the associated activities from other equipments. The critical path diagrams for each equipment would be gathered into a whole diagram for all setting to work carried out by WSTG on each ship and the critical path for all setting to work thus found. It was usually the major missile system.

The sea trials of HMS Fife were completed in 1966 with the project presenting.

WSTG had the task of setting to work o n the next ship HMS Glamorgan. I was joined in this task by Ken Hoad who joined the radar section after trying the computer section under Ivor Taylor and not finding it to his liking.This task was carried out through the summer and autumn of 1966 with Ken learning the new radar. I must say it was an enjoyable job and we not only got on very well but also established a nice routine. Our digs were usually in Newcastle, The Mariners, from where we caught a bus to Vickers Armstrong at Walker on the Tyne. Outside the yard was a small collection of shops where we bought our lunch and then to work. The evening meal was usually taken in the high street at the Odeon restaurant. All very civilised, I can’t remember any one else being involved on that job, which was quite unusual.

n the next ship HMS Glamorgan. I was joined in this task by Ken Hoad who joined the radar section after trying the computer section under Ivor Taylor and not finding it to his liking.This task was carried out through the summer and autumn of 1966 with Ken learning the new radar. I must say it was an enjoyable job and we not only got on very well but also established a nice routine. Our digs were usually in Newcastle, The Mariners, from where we caught a bus to Vickers Armstrong at Walker on the Tyne. Outside the yard was a small collection of shops where we bought our lunch and then to work. The evening meal was usually taken in the high street at the Odeon restaurant. All very civilised, I can’t remember any one else being involved on that job, which was quite unusual.

Having worked on two jobs already the setting to work on HMS Glamorgan was fairly routine.

However a once in a lifetime opportunity was to break the team up. I had been promoted to Tech Officer 2 in 1965 and Les Marks wanted to interview all newly promoted men after a year.

There had appeared on the WSTG notice board a request for volunteers for a job in Holland and quite a few people had encouraged me to apply but I was still thinking about it when I was summoned to appear before Les Marks for my annual review. After a routine interview with Les and the Radar section boss, as an after thought I asked if the Holland job was still open. The answer was yes and John Farmer and I were selected to go to Hengelo in Holland on the 1st January 1967.

This left Ken Hoad in the lurch on HMS Glamorgan to carry on STW and present the equipment for trials. I did feel a bit sorry about that.

Prior to our setting out for Holland we were gathered together to meet the Navy personnel who would be with us on the course.

They were Lt Cdr Vic Webb and four chiefs Terry Cadogan, Mike Baker, Geoff Titmus and Brian Healy. The project was led in Hengelo by Derek Dickinson from ASWE and Lt Cdr Jim Hall. The latter gave an intro on Hengelo and the Dutch, all very strange.

Our experience when we got to the factory was that the two residents from the project had but one brief, don’t rock the boat.

We were actually forbidden to use the Philips shop at HSA [ Hollandse Signaal Apparatten] in case we got corrupted, i.e. along the lines of “ there is no such thing as a free lunch”.

As I soon had a girl friend inside HSA this was soon circumvented.

We set off for Hengelo[O] on the 1st of January 1967, travelling via Dover, Calais, Antwerp and after an overnight stop in a motel at Breda [found out John snored, he found out I partially sleep walked] we arrived at the Hotel Royal in Hengelo.

All of the domestic arrangements had been made for us, which was not good. We were billeted two to a room with showers down the corridor and the rooms were not big.

There was a general feeling that the welfare man at Signaal had done a deal with the Hotel Royal. However the food was good and people friendly.

As a single man I was financially well off, having all bills paid and getting Foreign Service allowance. All of the others were married unaccompanied but that was their choice.

Addendum Dec 2004.

I am adding this section on hearing of the death of my friend John Farmer who accompanied me to Holland.

John passed away in early December 2004, just before our reunion, which he so badly wanted to attend.

I first met John in 1961 when he was our team leader on HMS Corruna when the Seacat missile system was installed. He immediately struck me as a nice man who enjoyed life and made the best of it. We spent many weeks working in the Rosyth Naval Base and always stayed in the Royal Hotel in Inverkeithing. As inverkeithing in January and February had little to offer the social life consisted of learning to play snooker on their small table and a drink at the bar.

One evening we had all had dinner and were relaxing when John remembered that the Top Secret crystals had been left out, when they should have been locked in the safe.

John’s character came to the fore, no panic, no phone calls, just a quiet drive back to the ship were the crystals still laid on the workbench. This approach saved the day and no one was the wiser.

Our paths crossed again on HMS Devonshire when, again as team leader, he was setting to work the GDS5. His gift for patience was sorely tried as the WSTG head Charlie Myles had a simple policy “no one in the office if there was a ship”. As a result John had a team of about a dozen to do three men’s work. He somehow managed to keep everyone happy. I remember working with Ray Rawlinson and Les Thomas on a simple manual sight, one port and one starboard. It was more fun than work.

In 1967 I volunteered to join a radar course in Holland at the Philips factory and I could not have been more pleased when I heard that John was the other WSTG man to go on the course.

On the 1st of January 1967 I caught the bus to 515 London Road where John waited with his car, a black and white Austin Cambridge, and we set off for Dover. I was later told that John had been at a hectic New Years Eve party the previous night/ early morning

After the ferry crossing we travelled on one of the few motorways in Belgium from Ostend to Brussels. Unfortunately each section of the concrete surface had tilted due to lorry weight and we progressed in a series of bumps and we were glad to get on the Antwerp road. I was not the most outgoing man but John soon found us a restaurant in Antwerp and a beefsteak was on our plate, well beefsteak seems to be an international word.

We had decided that the journey would be done in two days so as dusk fell we stopped at a motel in Breda.

As WSTG travellers we were used to sharing rooms, which was almost the norm in the 1960s, so we shared and I found out that John snored and he found out that I had a tendency to sleep walk or appear to be awake when in fact I was actually asleep. As John read late into the night he got used to that.

On arriving in Hengelo we found the Hotel Royal and were shown to our shared room, which was not very big and certainly not ensuite.

All other members of the class also shared, two to a room.

The Royal was a small family run hotel and we filled all of the rooms.

Apart from the family we shared the lounge/diner with a large old greyhound. On asking what it was called in Dutch we were told it was a”Wind Hund”. We were not surprised as it had a frequent and distressing problem with flatulence.

John and his love of life created many of the pleasant memories of the year spent in Holland. He was a keen fisherman and got a licence to fish in local canals, but in his typical style he always welcomed and encouraged the rest of the team to join in the days out. He never lost patience when the less interested and noisier members scared the fish away, after all we were all there to enjoy the day was his creed.

As the only one with a car, although I did later buy a Vespa, which we shared, he took us to Cologne and other places of interest and the Cambridge gave a trouble free years travelling.

However driving with John on the wrong side of the road could be a bit hairy. We once came out of a garage and John set of on the wrong side of the road. It was dusk and I could see lights coming on the same side of the road. John’s hearing problem with one ear did not help and it was the terror in my voice that eventually got him to wrench the wheel over. He was not too concerned, but that was John. In the same vein his habit of releasing the wheel while he searched all of his pockets for a fag and then a light could be a trifle alarming. You ended up praying that he would find the elusive cigarettes.

John was also a keen sportsman and although not playing football we did attend quite a few games to watch the navy lads play. In the summer he played tennis a lot on the local courts, which were close to my girlfriend’s home so I always went along to spectate.

By the summer I had been invited to stay in a Dutch home, Annemarie’s, and John moved out to stay at the Anninkpot, an out of town hotel. Doris came to visit and he met up with some WSTG people visiting Holland so I did not feel too guilty, well just a bit.

There is no doubt that John helped make that a year to remember as the Navy lads were a pretty miserable bunch, reluctant to spend money and missing their new wives, but that was their choice.

This is an example of the spirit of WSTG where we not only shared our work but our off work hours as well, in this case for months but usually for weeks at a time. It is I believe why in our retirement years we so strongly support the regular reunions and remember our friends.

Holland the course continued: -

After a few days the course started and we were picked up by car daily to be taken to the factory by the canal. We soon started a routine of walking home, which was very pleasant and after a few months I bought a Vespa scooter to travel about on, which was even more pleasant

It was soon obvious that this was a tough course and as exams were planned we asked to do extra time in the evenings. In the light of later knowledge it was a good job that we stopped that as Spring approached

Lt Cdr Vic Webb saw himself as the top man and was not amused when I beat him in the first exam. It was no big deal as we had been helping each other anyway.

It was at this stage that our on the spot men let us know their position.

We had been told that under no circumstances were we to take handbooks out of the factory, when we discovered that the Dutch members on the course were taking them all over Holland at the weekends we called “foul”. The answer quickly came back “don’t rock the boat”.

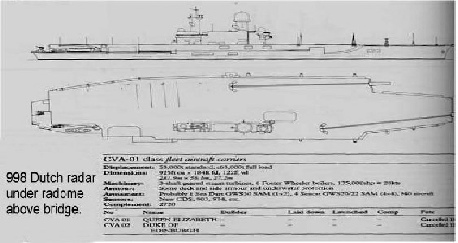

The Radar we were learning about was intended for the new generation of Aircraft carriers and their escorts the Type 82, of which HMS Bristol was to be the first.

It was very large Radar capable of detecting an aircraft in Range, Bearing and Height with an IFF [identification friend or foe] aerial attached to the main aerial.

The aerial had a total of five antennas, one IFF above, two HOM and two WAS so that range, height and bearing was checked every 90 degrees.

Waveguide switching was done mechanically and presented the design engineers with many problems. There was always someone ready to close the Transmitter down if the waveguide broke down and a travelling wave started to move down to the transmitter Amplitron.

The whole machine was controlled by a computer, which selected frequencies and did all sorts of clever electronic warfare stuff for height  finding etc.

finding etc.

The set needed a large ship as the aerial was a very heavy device and the number of cabinets full of PECs was extraordinary.

The course lasted until Oct and then we returned in Nov for another three weeks. John and I then returned to join the ASWE project. It was at this point that we were informed that the British buy of the 988 had been cancelled. The carrier had in fact been cancelled in 1966 before we even started the course, all that hard work for nothing.

This explained the hostile attitude of the Signaal hierarchy towards the end of the course, they knew what was afoot.

Back in 1966 a Seadart engineer had asked me the capability of the 992Q radar.

This Radar ended up being the surveillance radar for the later Type 42s and HMS Bristol.

Our job at ASWE now consisted of picking holes in the Signaal documentation, pretty soul destroying and totally pointless as the Radar had already been cancelled.

As far as I was concerned I was very happy with the outcome of the course for I was now courting a Dutch girl who in 1970 I married in Hengelo.

This fact was known amongst the project staff in Holland and the UK resident team. There was quite a lot of curiosity with regard to our relationship and on a contrived social invitation we were actually quizzed about it. When I returned to the UK the project manager immediately said there will be no trips for you back to Hengelo. Nice man.

I did my courting by means of trips back every 6 weeks on the Harwich-

I finally blotted my copybook with the project by trying to get a job with the Dutch Ministry of Defence. They, ASWE, were not amused and I was off the project within one hour of reporting for work next day. I was summoned to the project manager and threatened with dire consequences if I took the Dutch job. In hindsight I cannot see what the problem was as the radar had already been cancelled and surely I knew little of the political wrangling that was going on.

So it was back to WSTG at Milldam House and work in the radar section again.

I was fortunate that the Radar 992 was having an update with improved receivers so I rejoined the project to learn all about Parametric amplifiers. These were fitted to improve signal to noise ratios and hence better detection.

I did a refit at Chatham Dockyard on one of the early DLGs with the basic 992 transmitter, which consisted of some massive valves.

I worked with the Chatham radio centre staff and we achieved a harbour trial with no defects. The sea trial proved more difficult as a gold pin had been left out of the receiver connecters and detection was seriously down. It took two sea trials to find the fault and subsequently a test was incorporated into the setting to work to check this aspect.

1968 and 1969 passed with work on HMS Antrim and Norfolk at Fairfields and Swan Hunters yards and various RFAs [Royal Fleet Auxilliaries]. Every few weeks I went to Hengelo in Holland and 6th March 1970 was set as the wedding day.

I had already decided that travelling and leaving a new bride were not compatible so I asked Les Marks if I could leave WSTG for a static job. He had always seemed sympathetic because he told me that on leaving the Far East earlier in his career he had left behind a young lady, who he must have loved. His intention being to meet up again later and of course that did not happen. I had the impression that was one of life’s regrets.

His solution to the problem was to move me to Newcastle where HMS Bristol was building at Swan Hunters at Wallsend.

This seemed ideal as the work on Bristol would take two years and we could plan from there.

We were married on March 6th and travelled to Wideopen North of Newcastle to our new home at Brunswick Green. Actually a derelict coalmine but then a shiny new estate for the upwardly mobile of Newcastle.

There was not a happy ending, as no sooner were we settled when the build programme of Bristol slipped by one year. For the next year we travelled together around the UK from Glasgow to Plymouth, Portsmouth to Chatham. Annemarie saw many parts of the UK until setting to work at Swan Hunters started in 1971.

HMS Bristol was the only one of the class of escort ships intended for the new carriers, now cancelled. She had a very comprehensive weapons fit and a great deal of new digital ancillary equipment. Although my main task was the 992 radar, as the man on site I was the radar team leader and asked for staff as required.

Initially the equipment for contractor’s sea trials had to be set to work (stw). This was the echo sounder, navigation radar 974, gyro compass and basic radio communication equipment.

After these trials all other equipment would be stw. As can be seen from the photo HMS Bristol had a comprehensive fit and was treated as a trials ship for some of these equipments.

for some of these equipments.

It took a year to set to work all of the equipment and present for harbour and Sea trials. The radar section at that time included Norman Dibley, Pat Cross, Mick Smith, Brian Dubber, Vic Clements, and Jim Stephens with Freddie Lovegrove as section boss.

Freddie was a major problem for the team leaders because he carried all plans in his brief case and did not reveal them unless pressed. He was a long serving member of WSTG his roots going back to the outside erection party of the 1950s when it would seem such practices were common.

Those were the days when staff carried their own railway warrant pads and gardening leave was common.

As Bristol came near to completion I again approached Les Marks with a view to leaving WSTG, by this time there was a third member of the family, Odile born in Ashington.

As a result of that call we moved south to Portsmouth, setting up home in Cowplain in March of 1972.

I was still in the Radar section and travelling. The last of the Leanders, HMS Apollo and Ariadne at Yarrows and the first of the Amazon class at Vospers Woolston yard being the workload.

On our first visit to Amazon we saw that the 992 aerial had no guardrails and we refused to work on the ADN aerial. Although reluctant to take action, because of additional top weight, they fitted some lightweight rails and we were happy.

The Type 21s were built as a result of lobbying by shipbuilders who wanted to build ships for the RN without an input from ship department at Bath who they said had too high standards. The Controller of the Navy backed this to the hilt [surprise]. The result was a ship, which lacked stretch for Sonar 2016 and Seawolf and proved a fire risk with Aluminium superstructure and had to be strengthened. The class was popular with Naval Officers who had superior accommodation although ratings accommodation was below RN standards. No export orders were ever won for this design although this had been one of the original arguments.

The Type 21s were built as a result of lobbying by shipbuilders who wanted to build ships for the RN without an input from ship department at Bath who they said had too high standards. The Controller of the Navy backed this to the hilt [surprise]. The result was a ship, which lacked stretch for Sonar 2016 and Seawolf and proved a fire risk with Aluminium superstructure and had to be strengthened. The class was popular with Naval Officers who had superior accommodation although ratings accommodation was below RN standards. No export orders were ever won for this design although this had been one of the original arguments.

Pat Cross and I did the radar sea trials for the 978 and 992 and after successful trials we were allowed to take our wives on board for an extended look around. My Annemarie was now pregnant with our second child but still managed to see around the ship and enjoy a drink in the wardroom which as previously stated was furnished to very high standards. The WEO was a cracking chap, SD of course.

As Amazon completed I spent more time away, which caused more soul searching as to whether I wanted to be away from my young wife and family. I got very good advice from Len Brenchely who said that once you miss their growing up you can’t get it back and it’s not good for wives to be left alone.

I approached my boss Freddie Lovegrove who I think probably didn’t understand the problem but forwarded my concerns to Les Marks.

I was extremely lucky that he was in the planning stages of completely changing the sections in WSTG with a new Co-

It meant a lot less travelling but while the group established itself there was not much work.

The problem was that Les had made an autocratic decision to establish C group and it was met with much hostility from the existing sections who felt, quite justifiably, that there was no need for the new group and it was taking away their decisions.

On July the 5th 1974 I became the PTO 2 co-

I think it was a bit of Empire building on the part of Les marks who was prone to this bad habit.

When I asked what my terms of reference were in my new job as Refit co-

This proved to be an unwise decision as I was quite incapable of answering technical questions from other than the Radar section.

However as always in these cases common sense prevailed and after a settling down period I found that I had a job that I could get my teeth into and enjoy. My boss during my period as a co-

I was lucky in that over the period of my being the refit co-

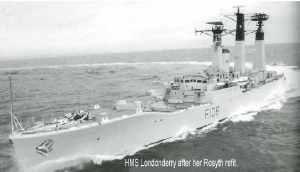

The 1978 refit of HMS Londonderry saw some considerable changes to this Rothesay class anti-

The 1978 refit of HMS Londonderry saw some considerable changes to this Rothesay class anti-

A third mast was fitted to carry the TYPE 1030 STIR radar, the gun was removed, a new propulsion system was fitted to check the quietness of waterjets and a CAAIS system was fitted to improve the ability to handle the amount of information being generated.

I was involved in co-

CAAIS stands for Computer Aided Action Information System and was a Ferranti designed system.

STIR stood for Surveillance and Target Indication Radar and was developed into Types 1022, interim STIR by HSA and 1030 by Marconi using back to back antennas.

The Leander conversions at Portsmouth, Chatham and Gibraltar Dockyards gave me a lot of work.

Usually at least a year before the refit started there would be a meeting of all interested parties to discuss the implications of the new weapons and sensors to be fitted.

In the case of the Gibraltar refit which was an Ikara fit plus many other new sensors this meeting was held at Ensleigh Bath and chaired by Les Marks. At this meeting I met the resident naval officer co-

Mr Marks later suggested that I went to Gibraltar to meet up with Robin Kerr. When I arrived, flying Dan Air on one of their De Havilland Tridents I was informed by Robin that the entire Dockyard hierarchy were assembled for an enlightening talk by me on every aspect of the refit.

Fortunately for me he had done his homework and led the meeting. Thank heavens as I had little knowledge of anything outside of my own field.

The Leander Conversions that I was involved in as WSTG co-ordinator.

The Leander design was such that it was easy to fit new weapons or sensors. It was decided that the first batch should be converted to Anti Submarine frigates. To this end the Australian Ikara GWS 40 missile system was fitted. This involved removing the 4.5 gun mounting and replacing it with the missile mounting called the Zareba.

The first fit was on HMS Leander at Devonport dockyard and I was not involved although WSTG staff were involved, Sid Porter as the team leader and Frank Moore doing the work. Sid was not a hands-

I was the WSTG co-

HMS Arethusa at Portsmouth, HMS Aurora at Chatham and I believe Naiad at Gib.

Apart from the Ikara there were updates on Radar, Electronic Warfare, Sonar and Radio Communications equipment. The electronic warfare fit was the Type 669 jammer designed to jam incoming anti ship missiles. This equipment which used travelling wave tubes as RF amplifiers proved to be extremely RF dirty and it is probably no co-

Eight ships in total were converted.

HMS Leander, Ajax, Galatea, Naiad, Aurora, Euryalus, Arethusa and Dido.

The RN felt that it required an Anti ship missile and the French Exocet met their requirements, there being no home grown missile.

The leander Batch 2 ships were therefore fitted with a four-

In addition the helicopter hanger was enlarged to take the new Lynx and the new STWS-

Unlike the Ikara conversion the 965 Radar was retained. The opportunity was taken to upgrade the Sonars with Type 184 and Radars 978 and 993 were replaced with 1006 and 994 and the UA 13 passive intercept. In all a nice work package for WSTG and the co-

E ight units in total were converted but I was only involved in the Chatham fit HMS Minerva and the Portsmouth fit.

ight units in total were converted but I was only involved in the Chatham fit HMS Minerva and the Portsmouth fit.

The final conversion of the Leanders was the fitting of Seawolf on the Batch 3 broad beam group. Because there was more room the Sonar 2016, Exocet and Lynx helicopter were also fitted although it was a tight fit and as much top weight as possible was removed.

All of these changes produced a very different looking ship.

I was lucky enough to be involved as the co-

was lucky enough to be involved as the co-

I worked with Norman Hawes the yard co-

Again this was a large workload for WSTG and the Aurora hotel, [ex NAAFI hotel] was well used by the many staff that journeyed to Chatham.

We have now progressed to about 1981 and it was time for a change of job, well not so much a change of job as a return to my roots.

The Radar section now had D M J White as it’s boss and he asked me to join the group again.

So I joined Jim Stephens and Vic Clements as one of his PTO 2s in July 1981.

The section was now run such that each PTO2 was given a ship to be team leader. As team leader we had to plan the setting to work assigning staff to each of the radars and ancillary equipment including the gyrocompasses.

My first battle was in Glasgow where some of the contractors were doing their own thing and grabbing the best work before the WSTG arrived. On being told that I would decide who STW the various radars I was met with hostility and intransigence. Fortunately DMJ backed me up and we were soon able to prove that we did not require contractual assistance at all. Their contract being a hangover from the days when some SPTOs were empire building. The ships then being STW were the Type 42s Southampton and Nottingham at Thornycrofts Woolston being my ships and the Type 22s of which one HMS Boxer was mine.

We also had many RFAs post refit to stw, the equipment included the navigation radar, the IFF and Gyros and following the Falklands conflict the Government bought three old oilrig replenishment ships to be refitted to carry out Falklands Patrols.

Fit only for the scrap heap someone must have put a few quid in a back pocket. As was the way in Mrs Thatcher’s days the contract went to the lowest bidder which happened to be Cardiff docks.

In all my days in WSTG I have not seen a worse ship refitter.

Protector, Guardian and Sentinel bought in March 1983 were ex Seaforth ships.

The team working on these boats were myself as team leader, Dick Hughes, Roy Wilkinson and Pat Cross.

We first had to do a pre installation visit to check all modifications and then try against considerable odds to set to work the basic fit on these ships. All this happened in one of the hottest summers. We use to come off the ships and fall in the nearest pub for a shandy.

The equipment was simple enough being navigation radar, IFF, displays and ancillaries plus a Gyrocompass fit.

It was the working conditions that were so bad and this should have been foreseen when the contract was placed. Cheap is not always best and this was one of the first examples of the way the Navy was to move away from getting the best to getting off the shelf and best commercial practices.

Because of the conditions I felt that the Trials authorities did not set the highest of standards in testing the equipment.

When completed the three ships staggered down to the Falklands collapsing on the way and having to call into Simons town for refits. I really don’t know if they were ever used to patrol the Falklands, it hardly seems possible and all had gone by the late 80s.

In the early 1980s the 965 radar was at last replaced. The Anglo Dutch 1022 radar was fitted on the then building Type 42s. Brian Dubber and Mick Smith were sent to Holland to attend a course and as the experts stw the 1022 radar on HMS Nottingham with me as their team leader. They were not the easiest pair to manage having an anti-

In the period 1982 to 1984 the radar section also stw [set to work] the Hong Kong patrol craft. These Peacock class vessels were 75% funded from Hong Kong and were built in Aberdeen by Hall Russell.

The class consisted of Peacock, Plover, Starling, Swallow and Swift.

Aberdeen was a long drive but we would do it in a day. From Newcastle on the scenery was breathtaking but arriving in Edinburgh and knowing that there were still many miles to go was a bit daunting. However the Granite City had welcoming guesthouses and the shipyard was close.

The same team that stw the Falkland ships also did the Peacock class the fit being the same.

It was whilst working on these ships that I at last got a promotion board, from PTO2 to PTO 1.

It seemed to most people in WSTG that we were largely overlooked in the promotion stakes, this may to some extent have been our own fault as we enjoyed the job so much that we did not move on the required every few years. This was even mentioned on my retirement even though I had travelled all of my working life and moved three times.

By spending so much time on equipment we all of course provided a large bank of knowledge that the fleet was able to call on but this was not in our interest.

So now was the time to get the books out and try and learn about the world outside of WSTG. The latest projects, schemes and management skills (why did they seem so obsessed about drunken members of staff and how to deal with them).

Both Jim Stephens and myself were the only two PTO2s selected for this board.

In 1984 the whole of WSTG was in turmoil because an announcement had been made that the organisation was to fold and our work was to be contracted out, another bit of Thatcher dogma.

Many members of WSTG decided to move on before the axe landed, obviously trying to get the best jobs and avoid moving outside Portsmouth.

Amongst these was Bob Blofield, the PTO 1 in charge of the Underwater section and Submarine work.

Our Captain at the time was Estlin who had been in WSTG as a Lieutenant many years previously. I had met up with Keith Estlin many times on the DLGs when I worked on the 992 radar.

Whilst he was away on leave the decision was taken to promote Fred Guy into Bob Blofield’s now vacant post.

Just before Easter Captain Estlin returned and much to my astonishment countermanded the decision and asked me if I wanted the post, this being based on the fact that I had a board and Fred did not. I was more or less told by Estlin that it was an opportunity not to be turned down.

So after Easter I was to be the new head of Under water weapons, electronic warfare and head of Submarine work.

Click to continue on next page ….