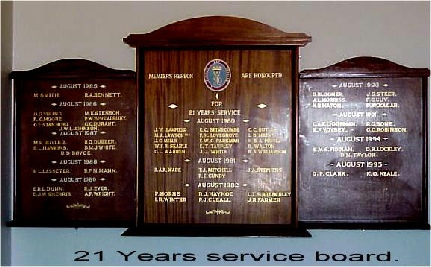

Weapons Systems Tuning Group Reunion

© WSTG Reunion Committee 2016

Go to top of page

Head of the Sonar section 30th April 1984-13th March 1996.

In WSTG the various sections were slightly remote from each other, maybe because we worked in different parts of the ship.

So I came to a section of about thirty people of whom I knew very little.

I shared an office with D M J White, who ran the Radar section and who was my last PTO 1.

We worked together in a large office on the ground floor, first left as you entered Milldam House.

Milldam house had been the Headquarters of the Royal Engineers when my father was serving in the 1930s and he certainly visited the house as an RE. Now it is the Portsmouth Registrar and couples enter to be married.

I was of course only in the post Temporary and Geographical, this meant that I still had to pass a promotion board and this proved to be a major obstacle.

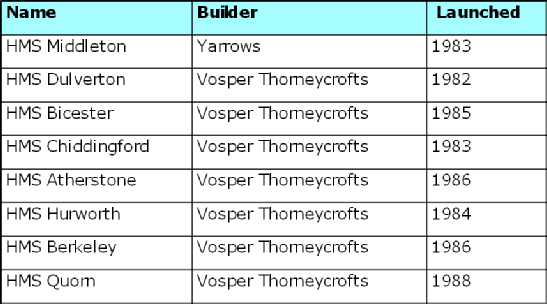

The ships being STW at that time were.

- Type 42s Gloucester, York and Edinburgh.

- Type 22s Boxer and Beaver.

- Trafalgar class nuclear attack submarines. HMS Turbulent.

- The Hunt class mine countermeasures vessels. HMS Bicester.

My terms of reference read: -

Initiating contract action and subsequent financial control of contracts including reporting forecast of outturn and long term costings to meet future commitments for the next ten years.

Staff.

Sonar

Mick Butler PTOII [Portland], Dennis Collard PTOII, Ray Cundy PTOII [Portland], Paul Blackmoore III, Colin Game III, Gerry O’gorman III, John Anderson IV, Geoff Clark IV, Mick Stenson IV, Dave Taylor IV, John Crockford IV.

Mine Counter Measures Vessels (MCMV)

Chris Whiting II, Frank Moore III, Colin Parr III, Dennis Gaffney IV.

Submarines. DCB/RNSH.[Royal Navy Sub Harpoon].

John Sedgewick II, Gordon Hoare III, Bob Irwin IV.

EW. (electronic warfare).

Don Meakin II, Bill Merewood III, Roger Fiddy IV, Keith Rickman IV.

The equipments that my group had to STW were: -

On the surface ships. Sonars 2016 medium range active/passive search and attack, echo sounder 778, STWS Mk 3 [shipboard Torpedo Weapon System]. 182 towed submarine decoy system, 162M bottom search sonar, 2008 underwater telephone, 2009 underwater IFF, 2010, 2015 Bathythermograph, 2031 towed array.

Electronic warfare equipments 670, 675 jammers and UAA1 passive intercept.

On the submarines the Sonars were the 2020 main sonar, 2007 a low frequency passive sonar, 2019 and a similar set of small sonars as the surface ships. The EW fits were UAC with the aerial fitted on a periscope.

On the Hunt class mine hunters the main sonar was the 193M hull mounted mine hunting sonar, the Mil Cross mine avoidance sonar, the sonar 2059 which worked with the PAP vehicles and the usual fit of echo sounders etc.

The section also STW the CAAIS DBA 4 action data automation system and the various mine destruction systems PAP 104, MS 14 magnetic sweep, Scarab mine destruction, the MSSA Mk 1 towed acoustic sweep and the Oropesa Mk 8 sweep.

The section also covered any work on RFAs and shore establishments such as HMS Collingwood.

To carry out these tasks I had an excellent team of HPTOs and PTOs and some contractors from Plessey, Ferranti, EMI, Thorns, Gresham Lions and Grasbys.

I soon found that our contractor manning was excessive and we gradually cut it back taking on the STW of equipments like 2016 in house.

Some of the team were based away from Portsmouth. I had staff in Barrow in Furness and at Portland where the Sonar project people were based at Southwell.

Over the years the Portland staff gradually were moved away but the Barrow office was manned up to the day I left.

I had the good fortune to have a helpful colleague in the same office, D M J White and an understanding boss Tony Morris. Both were essential in the early days as I got to grips with new staff, equipments and financial delights such as forecast of outturns. These were an educated guess as to how much you would spend in the current financial year on contractors.

As it was April I had the whole year ahead of me and the first meeting with Captain Estlin within a week.

Asking for over a million pounds based on my scant knowledge seemed a bit risky but we went for it.

As I was temporary and geographical in the post the main obstacle over the next couple of years was getting through a promotion board. As I was still fairly shy this proved to be a serious problem.

The promotion board gave me no plus points for actually doing the job of an SPTO, which of course was designed to avoid corrupt practices, and also continued to ask questions based on what the board members knew.

I was unfortunate to get some old fashioned overseers from the northern factories who seemed to think that I should be cogniscent of their jobs to the nth degree.

However at what I believe was the third attempt I got through “Alleluia”. They actually asked questions on Sonar and ships.

Again D M J White (Knocker) assisted greatly by giving me dummy interviews.

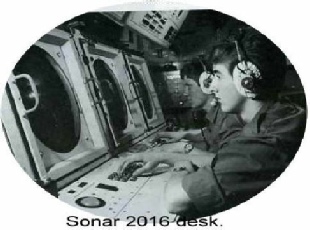

As an SPTO I always felt that my staff should be the experts on the equipments they worked on and not me. I always found it difficult to understand the sonar displays which were so different from the radar presentation although the object was often the same, to detect a target and present it’s range and bearing, speed and depth.

In sonar it always seemed to be complicated by water conditions such as salinity, temperature and layers but the lads seemed to understand it all.

The sonar 2016 was a complicated beast and we initially employed Ferrantis to assist us but the staff felt that we could go alone so that’s what we did. When 2050 came along, the successor to 2016, after some help from Ferranti we set it to work ourselves. Dennis Collard the HPTO was always enthusiastic about doing work in house and the excellent PTOs such as Leon Raymond and Geoff Clark responded with equal enthusiasm.

Leon had joined us from another section who rated him very poorly, their loss was certainly our gain because as an ex Copenacre apprentice he was hard working and very bright

I should not give the impression that all of my staff were the same, as in any group there were good and bad, energetic and lazy, clever and not so clever.

One PTO in Barrow took the earliest opportunity to wind me up by phoning up as late as he could on a Friday afternoon demanding immediate action to get half a dozen people to the Gare Loch for a submarine. My reaction that I would deal with it on Monday caused him to threaten dire consequences if immediate action was not taken.

You soon learn to deal with such people who have an over extended vision of their own importance. He never did get promotion beyond HPTO.

He was the only member of my staff who a commercial firm complained about, not without good reason I felt.

Another PTO was on very extended sick leave, which was treated with suspicion by my boss and me. His problem was a bad back, which prevented any activity. His come uppance came when he was found on his caravan roof painting by the medical detectives.

He did not last long in my section and moved to the 2016/2050 project team.

One HPTO sent to the Tyne phoned in from Plymouth, doing his own thing for personal reasons. That might have been fine for the previous head of section but not for my boss or me. He found himself with a job change whilst he was on leave, not my doing but I did agree.

One problem in the MOD is sacking people who are not up to the job. In WSTG good health was essential but it took me two years to sack someone who was obviously ill and unable to carry out his duties in any way at all.

Verbal warnings, written warnings have to be repeatedly given only for the personnel department to come back with “give him one more chance”. Eventually he left under the most advantageous package on the grounds of ill health and we were all happy.

All the rest of the team were hard working and consciences with excellent HPTOs.

WSTG traditionally recruited from the Dockyards and ex service people but many of those mentioned above came through the Copenacre apprentice scheme. This was a high quality scheme and many of the lads went on to university. However they all came to WSTG for their work experience and the type of work proved so tempting that a lot came back as permanent staff and soon moved up the promotion ladder. WSTG was lucky to have this source to recruit from as the Dockyard apprentice schemes crumbled.

The EW section claimed an important first when the initial female apprentice from Copenacre joined Ron Dunns team. There had been some discussion amongst the heads of sections but I had no problems having a young lady join our group.

As would be expected from again an ex Copenacre apprentice she was a clever girl and gave me no headaches and I made the right decision by putting her in the EW section where Ron Dunn took her under his wing.

The ships 1984-1996

As I started my career as an SPTO the section was STW the stretched version of the Type 42 destroyers HMS Gloucester, York and Edinburgh at Vosper Thornycroft, Swan Hunter and Cammell Laird respectively. These ships completed in 1985 and 1986.

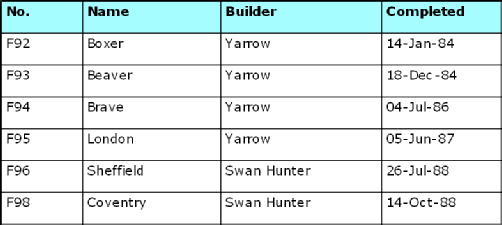

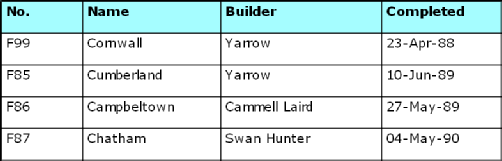

Also in build 1984 –1989 were the stretched Type 22s as follows: -

At the end of 1982 four more Type 22s were ordered to replace Falkland losses, but they were redesigned to form the Batch 3s.

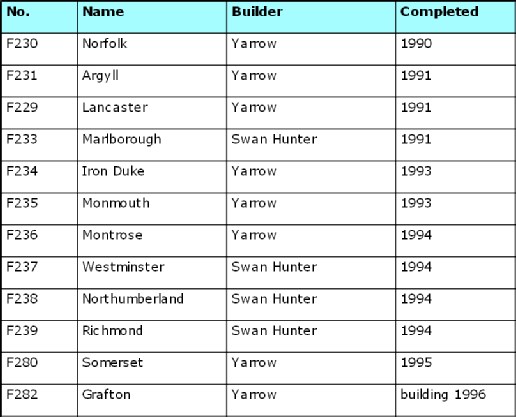

The Navy and the Treasury now wanted a cheaper frigate relying on the 2031 sonar and stealth features in its design.

T he Type 23 was optimised for towed array operations and employed a unique combined diesel electric and gas turbine propulsion system.

he Type 23 was optimised for towed array operations and employed a unique combined diesel electric and gas turbine propulsion system.

Ships of class that WSTG was involved in either as first of class or in total when I was head of Sonar section .

.

There were further Type 23s but I had retired when WSTG were setting to work.

Submarines.

The Trafalgar class were in build as I took up my Head of section post in April 1984.

Turbulent was carrying out her sea trials with Roy Woolgar representing WSTG and the section on board.

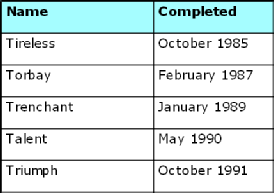

The following boats were completed during my term as head of the Sonar section all being built at the Vickers yard at Barrow in Furness.

In spite of all the predictions WSTG was then heavily involved in the setting to work of the Upholder class with Dennis Collard, Frank Moore and Roger Eves as the team leaders on site.

We had been invited to set to work the periscopes, a new task for the section, which we grasped with both hands. Dennis and I had to train the contractors Barr and Stroud that we were the boss and they did as we asked.

Upholder as first of class was set to work by the projects with our people on site learning the ropes.

Upholder as first of class was set to work by the projects with our people on site learning the ropes.

We set to work the rest at far less cost to the MOD. Going by the difference in stw the periscopes I would guess that we cost 20% compared to the first boat.

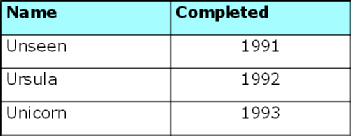

The last three boats were built at Cammell Lairds on the Mersey.

When we started long term costing on the Trident programme in 1984 there was a general feeling that WSTG were unlikely to be setting them to work as Vickers were lobbying hard to get a through life contract which would include the setting to work.

However one of the assets of WSTG which had played a part in our survival was that we were independent and when different weapon systems had to be integrated this was an essential asset.

If a problem arose for example in linking the periscopes to an AIO system we had no axe to grind and would sort the problem. The manufacturers always tended to blame the other guy and an impasse ensued.

So WSTG became the STW authority for the follow on boats after Vanguard had been STW by the various projects. I spent many months preparing the contracts and getting staff prepared for what was a major task with no room for error. It involved a lot of travel to Newport in Wales, Plesseys], Hook in North Hants, [Gresham Lions], Glasgow [Barr and Stroud] and the Project homes at Portland.

at Portland.

All of the boats were to be built at the VSEL yard at Barrow in Furness.

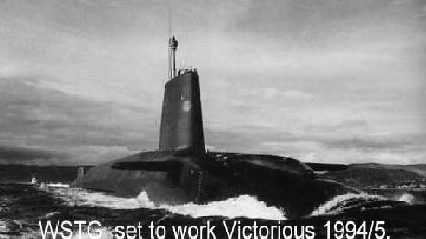

HMS Vanguard project set to work new systems completed 1993;

HMS Victorious WSTG set to work completed 1995;

HMS Vigilant WSTG set to work started when I was head of section but I retired before completion.

Mine Warfare Vessels

The Hunt class were in build in 1984 with five already built. When I became head of section HMS Middleton was being set to work with Dave Taylor and Frank Moore doing the sonar, AIO system and mine hunting equipment . Chris Whiting was the very much hands on team leader. Later Ray Callaghan became team leader on Chris Whitings much deserved promotion and when Ray retired Frank Moore was promoted to team leader.

The Hunt team and later the Sandown team were always a close knit group who worked well together and always looked after new youngsters who joined their group.

Adrian Hunt, Andy Cotterall and Carl Potts were lucky to join that team.

M ost of the Hunts were built at Vosper Thornycrofts at Woolston but Yarrows also had a facility to build these GRP ships where they built Cottesmore and Middleton. There was I believe a problem because the atmosphere on the Clyde was damper than that at Southampton but that may have been just a rumour.

ost of the Hunts were built at Vosper Thornycrofts at Woolston but Yarrows also had a facility to build these GRP ships where they built Cottesmore and Middleton. There was I believe a problem because the atmosphere on the Clyde was damper than that at Southampton but that may have been just a rumour.

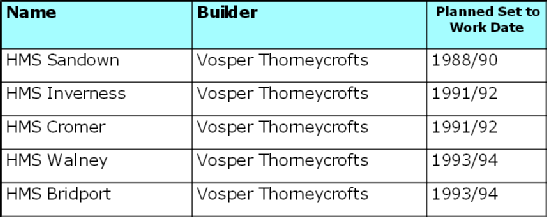

Designed as a cheaper alterative to the Hunt class by reducing the number of roles, hence the designation “Single Role Minehunter”. This next class of minehunters was set to work by WSTG, with Frank Moore as the Team leader.

As was the norm the First of Class was Set to work by the project teams although they relied heavily on the expertise and willingness to travel of the WSTG staff.

The 2093 Sonar had many teething troubles and many were the meetings at Templecoombe chaired by an ever over optimistic project manager who later joined the company.

In addition to the ships we set to work the Trainer fit at HMS Collingwood. This task seemed to tend to infinity because the usual MOD services team had been dispatched by dogma and the build was put out to contract. The contractors had little or no idea what they were about and many basic problems ensued. The gantry holding the towed body was first to collapse. As usual WSTG fulfilled all of its obligations and more.

The MOD project manager was John Price who initially was sceptical of WSTG’s relaxed programming method, but it was he who let us down in the end.

Ships set to work by WSTG when I was Head of Section.

All built by Vosper Thornycro ft at Woolston.

ft at Woolston.

Above dates is the planned setting to work dates, but as delays occurred with the Sonar the setting to work tended to carry over into the operational period.

The team spent a lot of time on the Trials ranges at the Kyle of Loch Ailsh in Scotland.

In addition to these warships the section as with the rest of WSTG had the responsibility of setting to work relevant equipments on Royal Fleet Auxiliaries new or coming out of refit, shore stations, such as HMS Collingwood, Engadine and survey ships.

The Equipment

Having listed most of the ships the Underwater/electronic warfare/Submarine section worked on between 1984 and 1996 I will now list the equipments worked on. A few were set to work with the assistance of contractors who were managed on site by WSTG staff and controlled through my office. The budget for this assistance was about £1 million per annum.

Sonars

Echo sounders

Mike Stenson was King of the echo sounders, having worked on them for most of his career but I did eventually get him to add SEAPADS to his repertoire.

SEAPADS. Underwater environment prediction system. It provided real time advice to Command on the most effective deployment of units and sensors. This is a particular requirement for Towed Array sonars. The equipment uses stored oceanographic information and inputs from on board sensors such as the bathythermograph.

Type 778 in general service throughout the fleet.

Type 780 a hydrographic system fitted to Trafalgar class submarines.

Type 162M this is the oldest sonar in the Royal Navy, having been developed in1948 for bottom searches in confined waters. Fitted to all ships.

Type 182 a surface ship towed decoy transmitter. Towed a mile aft of the ship it transmits the signature of the ship towing it, this acts as a decoy to submarines.

Type 2007. Passive search and detection sonar. This is a submarine sonar, which uses steerable beams enabling the submarine to steer a straight course while a search is made for hostile submarines. A freq of 1-

Type 2008. Underwater telephone. Fitted to all ships.

Type 2009. Underwater recognition system. IFF.

Type 2010. Underwater teletype receiver/transmitter.

Type 2015 Bathythermograph. Lowered through the water it detects thermal layers, which effect sonar performance.

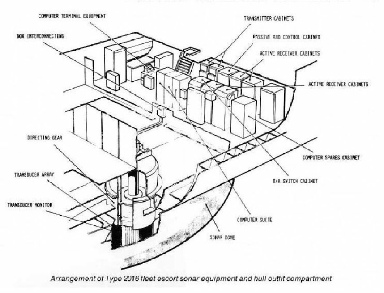

T ype 2016 Medium range active /Passive search and attack sonar fitted 42s some 22s. This large sonar can have bow or hull mounted transducers but in RN service it had the hull-

ype 2016 Medium range active /Passive search and attack sonar fitted 42s some 22s. This large sonar can have bow or hull mounted transducers but in RN service it had the hull-

Type 2019 Spectrum analyser for low frequency sonar systems.

2 020.Passive and Active bow mounted Sonar. Fitted to the T class Hunter-

020.Passive and Active bow mounted Sonar. Fitted to the T class Hunter-

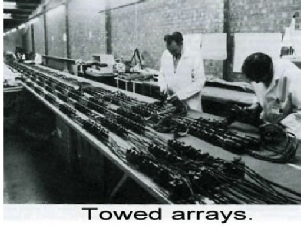

Type 2031Z. Towed array system, fitted to all frigates from Type 22 batch 2. Used the innovative ”Curtis” architecture developed at ARE Portland. Provided a multi octave broad and narrow band analysis facility. We were fortunate to recruit Paul Madden at the time this was being fitted in the Type 22s. Although we threw him in at the deep end he handled STW and trials well, liasing with projects and manufacturers. We worked hard against the inertia of the system to get him fast track promotion, which he eventually got.

Type 2039 Submarine Bathythermograph.

Type 2060 Expendable Bathythermograph. Does the same job as the others but is not recovered.

Ty pe 2026. Passive towed array sonar fitted to Submarines. Set to work by Andy Cotterral.

pe 2026. Passive towed array sonar fitted to Submarines. Set to work by Andy Cotterral.

The system consists of a multi octave towed array clipped to a fin of the sub by the tow cable and on board processor and display system. The system provides surveillance and classification from both towed and flank array systems.

Type 2032 is an update package for 2020 to give a limited narrow band facility.

Type 2050. This set replaced the 2016 and had the bow mounted dome, this necessitated a change to the shape of the stem to 22s so fitted to prevent the anchor damaging the array. The 23s were designed for the fit.

Contractor assistance was initially required from Ferranti but again we recruited from another section, he was rejected for not showing the right body language. This was due to the fact that as a bright Copenacre apprentice he was totally fed up with being a bag carrier for one of the less bright PTO3s. We immediately sent him on a 2050 course at Ferranti Stockport and he became our 2050 expert. His talent was noticed at Ferranti and he always had their cooperation. The team setting to work were Leon Raymond, Geoff Clark and Dennis Collard as team leader later another young man, Rodney Hall, rejected by the missile section joined us and after the 2050 course proved to be excellent.

Type 2040. In spite of continued predictions of the demise of WSTG and statements from on high that we would not be setting to work the Type 23s, the Trident class and the Upholders we in fact did all three types and for good measure added the periscope systems to our list of equipments.

The 2040 was a combined Active, passive and intercept suite of sonars designed by the French company Thompson Sintra and derived from the ELEDONE sonar system and fitted on the Upholder class. This was a large fit and we had assistance from French Engineers in the setting to work. Interestingly the French engineers could not believe that our skilled staff were so underrated in their financial rewards and status. On the continent engineers are of course highly rated and paid.

Frank Moore was the Team Leader on this fit, doing his usual dedicated job and getting on very well with the French Engineers.

The system provided the following functions. Passive detection, Automatic anti jamming, Passive adaptive processing, Automatic detection and tracking, Interception, Active capability, Classification, Hostile weapon alarm and contact motion analysis.

Type 2046 Passive hull mounted. Fitted to Upholder class and set to work by Andy Cotterall.

T ype 2054. This was massive sonar fitted to the Trident class of submarines.

ype 2054. This was massive sonar fitted to the Trident class of submarines.

This was a passive/active intercept and towed array sonar suite.

As it was such a large set WSTG was unable to build up the necessary expertise to set to work the equipment. Marconi underwater systems were employed with Roy Woolgar, WSTG, as the overall system leader. So in this case most of our work was in contract administration over many years before and after the actual setting to work.

Most classes of warships had a torpedo launching system. On the Type 42 it was the STWS 3, which had two tubes firing by means of compressed air the Stingray or Mk 46 torpedo.

The section recruited an ex navy chief Chris Benson who became the king of the torpedoes. He later moved on to set to work the Magazine launched system fitted on the Type 23 frigate.

He was of course ably supported by Geoff Clark and Carl Potts who can be seen in the WSTG video “All Systems Go” doing their stuff on a Type 23.

MCM SONAR SYSTEMS

Sonar 193M

Fitted in the Hunt Class MCMVs.

The MCMVs had a dedicated team of WSTG engineers. During my time as Sonar Head I had Chris Whiting, Ray Callaghan and Frank Moore as the on board team leaders. Both Chris and Frank were very much hands on men and Ray in his last couple of years before retirement more an admin man. The teams were completed by Dave Taylor the 193 expert Colin Parr and Dennis Gaffney.

The 193M was a sector scanning minehunting sonar. With short range and operating at two frequencies it provided detection and classification of both moored and ground mines.

Sonar 2093

Fitted in the Sandown class of Single role Mine hunter ships of the Royal Navy this is a variable depth, multimode mine hunting sonar.

We also set to work a complete SRMH system in HMS Collingwood.

Because of the complexity and long development time of this set we were forced to use some contract support from Plessey at Templecoombe.

Frank Moore and myself attended numerous meetings at Templecoobe as the equipment hit so many teething troubles, not too arduous a task as there were some nice pubs in that area.

It did mean ships and Collingwoods programmes were constantly delayed. Not so serious at Collingwood as the tried and trusted method of using MOD engineers to carry out the installation had been abandoned and the task had been put out to private contractors. There work was beset by continuous design errors, which seriously delayed the completion of the installation.

The sonar’s problems were not unexpected and were eventually overcome. This was the world’s first variable depth, multi mode mine hunting sonar.

Much of the electronics was in a watertight body, which was lowered through the ships centre well. Any problems in this area involved the difficult task of raising the body and if necessary lifting it off the ship.

A Modified CAAIS system was fitted on the Hunt class as their AIO system. WSTG set this and the display system, which included two plotting tables to work. Frank Moore as the team leader had a major input in this. On the SRMH the NAUTIS-

The team that had set to work the HUNTS moved over to the SRMH class. Since the early HUNTS some people had been promoted and new faces had moved in to replace them.

Frank Moore, Geoff Clark, Carl Potts, Daniel Kitchen with contract support ensured that we met all trials requirements. Their patience often being strained by failures of the 2093.

Other equipment on the HUNT and Sandown class included the MSSA Mk 1 OSBORN.

This was an acoustic minesweeping system which towed by the ship simulates the ships acoustic signature and thus causes any mines waiting for such a signature to explode.

Two bodies were towed. The TAG, towed acoustic generator and the TAM or towed acoustic monitor.

Both classes deployed the French PAP remote controlled mine disposal system. Manufactured by ETA has the capability to hunt and destroy ground and tethered mines. Like mini submarines the bodies are lowered over the ships stern to hunt mines already detected by the sonar. Its destructive weapons are a bomb and an explosive cutter. It’s position being controlled by an on board joystick.

My section also included the setting to work of Electronic Warfare equipment.

Jammers

Type 669. Used to confuse sea skimming anti ship missiles, this involved detecting the frequency of the incoming missile and returning it at high power and bounced off the sea some distance away from your own ship. Don Meakin, Ron Dunn and Keith Rickman were the experts.

This was an extremely dirty set, scattering nasty rays about. Most of the people who worked on it met an early death.

Type 675 was fitted on later 42s, 22 batch 3 and 23s.

Passive intercept

All later intercept electronic warfare equipment used the same system of having a library showing frequencies, pulse length, rate etc. The set could thus tell the operator the source of an intercepted signal and its threat.

Sets worked on by my section were: UAA1 surface ships and land based test site at Portsdown, UAC T class submarines, UAP T class and Vanguard class Submarines.

ESM systems for submarines.

Outfits UAB,UAC,UAP. The early UAB or UAC replaced the UA-

UAC was followed into service by UAP on the Upholders and Vanguard class. The new set has a frequency range covering all of the required radar bands. With automatic alarm levels, a minimal mast exposure using the search periscope and the ability to store to disc new data the set offers all requirements of ESM, surveillance, self protection, data gathering and over the horizon targeting for weapon release.

Next we have the Submarine AIO systems for which we used support from Ferranti and Gresham Lion to set to work both the computer and torpedo equipment with a WSTG team leader and co ordinator.

On the hunter Killer class the DCB was fitted. The submarines sonar’s, periscopes, ESM and navigation equipments are linked to the AIO computer. Weapon settings are passed to the wet end {torpedo tubes]. After firing information from the wireguided torpedo is fed back to the system to allow updates to the weapon.

On the Upholder class the DCC, a Ferranti Bracknell, system was fitted. The system was designed to deal with wireguided torpedoes, antiship air flight missiles and mines.

It was completely set to work by Ferranti.

On the Vanguard class the SMCS [Submarine Command System] was the fit. Designed by Dowty-

Using the latest, 1990, technology it had much greater processing power than earlier equipments and room for future expansion.

We used Gresham Lion Engineers to set to work this equipment with Roger Eves WSTG as team leader.

Finally we have the Periscope systems on submarines. Traditionally this was not a WSTG task. Barr and Stroud, later Pilkington Optronics Glasgow, being the designers, installers, setting to work team and maintainers.

I discussed this anomaly with my staff, Dennis Collard and Roger Eves and everybody expressed an enthusiasm to do this task in house.

The project manager Allan Cave agreed that we could be the setting to work authority in line with WSTG terms of reference.

We took on the Upholder and Vanguard masts. These being Search, Attack and Optronic masts.

In discussions with the project manager he asked how much money I had in for Contract support, indicating that half a million might be about right. As I had one million for the whole boat I had to tell him that £40K was my calculated budget based on two engineers for eight weeks.

As soon as our first Upholder started, HMS Unseen the second boat, it was easy to see the problem.

Our way of asking for support was to send off a form requesting the exact number of engineers required to the company, in this case two with the indicated skills. This having been agreed with the manufacturer in previous meetings.

I had a phone call from Dennis Collard telling me that a gang of about ten men had turned up, each with a specific skill i.e. one to undo the screws and another to remove the lid and another to check the wiring etc etc.

A quick phone call to Glasgow reduced the team to two as requested. It was easy to see why the first boat had cost so much and why Barr and Stroud had been on a very lucrative gravy train.

In Dennis Collard and later Roger Eves I was lucky to have enthusiastic engineers, they both worked well with Barr and Stroud and gained considerable expertise on the masts.

Details of the masts

The CK 035 search periscope.

Fitted on the Upholders offered the following features.

- three powers of magnification.

- artificial horizon periscope.

- stabilisation of TV and visual line of sight.

- optional thermal imager

- optional image intensifier.

- torque drive.

- remote operation.

- digital display of data.

- eyepiece display data.

- range transmission and display

- bearing transmission and display.

- TV camera.

- 35mm photography

- electronic support measures.

- Communications antenna.

The CH085 attack periscope

This is a low profile mast with similar features to the above but as the attack mast Low Light cameras, thermal imaging and TV camera become more important.

When I was first shown the intended masts for the Vanguard class it was immediately apparent that these were going to be large boats. The masts could be seen from the outside of the factory at Anniesland, Glasgow, poking through the roof.

The first boat was done by the project, using Barr and Stroud engineers and the subsequent boats were ours.

Pilkington optronic mast. Two were fitted to each boat each having these features:

- thermal imager.

- combination of TV and NIR sensors.

- stabilised line of sight.

- integration with submarine weapon system.

- electronic support ESM.

- communications antenna.

The mast features multiple pre-

The setting to work of the Vanguard class was the high light of my time in WSTG. I had started my career in the era of valves and ended it with every piece of equipment having its own computer.

In 1961 there were dozens of shipyards building ships much the same way as the first iron clads had been built, out in the open small sections at a time.

By 1996 we were down to half a dozen yards equipped with automatic welding, synchro lifts and covered building halls where massive prefabricated sections were welded together.

In 1995 my boss Knocker White informed me that he was retiring early and at his suggestion I asked if I could retire in March of 1996 as I had the full 40 years paid in which qualified for maximum pension and it would be preferable to retire going into summer rather than into winter.

This was agreed to by the personnel section at Bath although my AD (Assistant Director) did say he expected me to work hard up to the last day and no slowing down. A bit rich from him really as far as I am aware he never got into first gear.

By March my new boss was Dave Metherall and it was time to go. I declined the offer of a royal visit from some one in Bath who didn’t even know me and would read a prepared speech and retired on the same day as Mick Stenson, one of my PTOs. Our presentation was by Chris Whiting. Much nicer.

I have continued a relationship with WSTG and am now one member of a committee that organises reunions and maintains the large archives.

WSTG did not last much longer being officially wound up in 2003, the whole ship concept having won the day.